Porous structures are used in many industrial applications such as thermal insulation, packaging and filters, food and beverage, pharmaceuticals, but also in biomedical applications such as scaffolds for bone tissue engineering (TE). To understand, simulate and eventually predict the behavior of porous structures during loading in order to assess their functionality, a thorough knowledge of the relationship between their morphology and mechanical behavior is needed. Also, and specifically for bone TE scaffolds, calculating or predicting the local strains under mechanical loading can be useful to analyze strain-dependent cell behavior on the surfaces of the porous scaffolds.

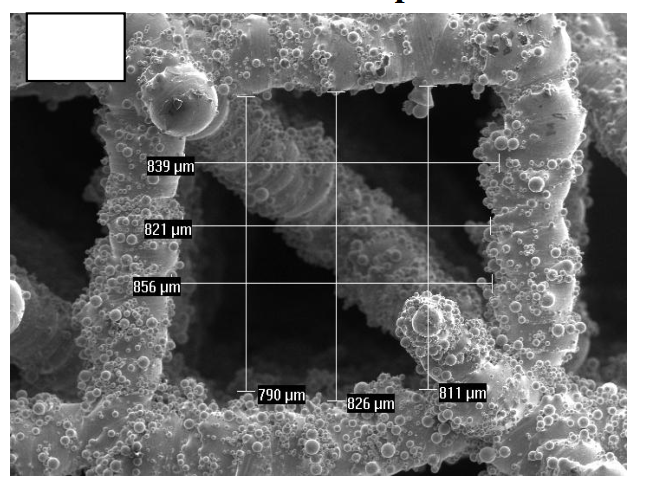

This research analyzed rapid prototyped (RP) porous Ti6Al4V structures, to be used as bone TE scaffold, by correlating structural characteristics (meso- and microscale morphology) with mechanical performance (stiffness, strain distribution and failure) using quantified 3D, multimodular characterization techniques. This analysis enables design optimization and RP production feedback in function of the envisioned requirements. Because it is known that, apart from the strains present on the surfaces of the scaffold, also the surface topology has a significant influence on the cell behavior, the effect of surface modification of the porous Ti6Al4V scaffolds on their local strain distribution and mechanical behavior has been assessed.

A comparison with scanning electron microscope (SEM) stereoscopic imaging and geometric considerations.png)