Abstract

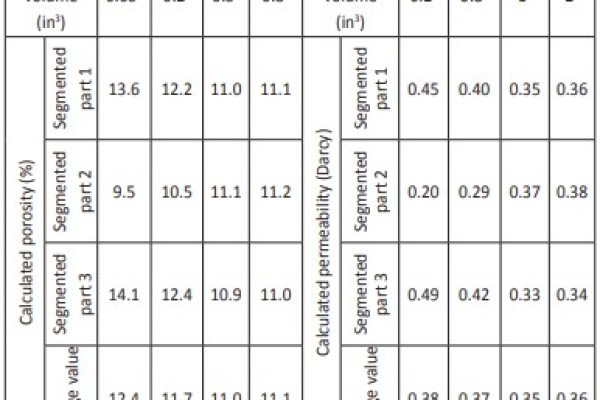

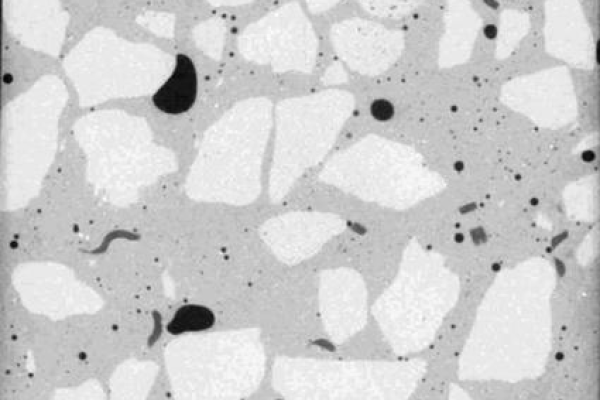

Volumetric quantification of ore minerals is of interest using non-destructive laboratory X-ray tomo-graphy, as it allows high throughput, fast analysis, without any/limited sample preparation. This meanstraditional chemical analysis can still be performed on the same samples, but good information can beprovided in a very short time assisting in exploration, mining and beneficiation decision making as wellas sample selection for further chemical analysis. This paper describes a case study in which tungstenWO3/scheelite is quantified in 35 mm diameter drill core samples and compared to subsequent tradi-tional chemical analysis for the same samples. The results show a good correlation and indicates thatlaboratory X-ray CT scanning could replace the more time consuming traditional analytical methods forore grading purposes in some types of deposits. Different image processing methods are compared forthese samples, including an advanced thresholding operation which reduces operator input error. Themethod should work equally well for other types of ore minerals in which the mineral of interest is themost dense particle in the scan volume, and for which the bulk of the particle sizes are at least 3 timeslarger than the scan resolution.

Keywords: Ore minerals, X-ray tomography, Tungsten, Scheelite, Micro-CT.

Full text available here.

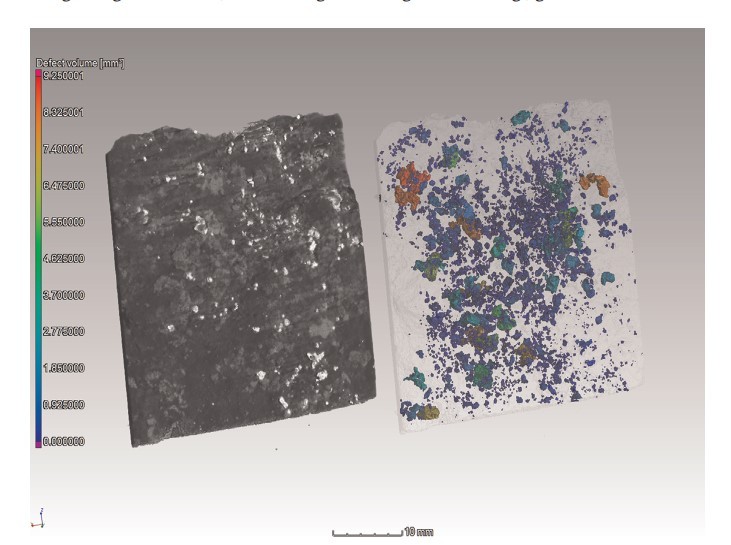

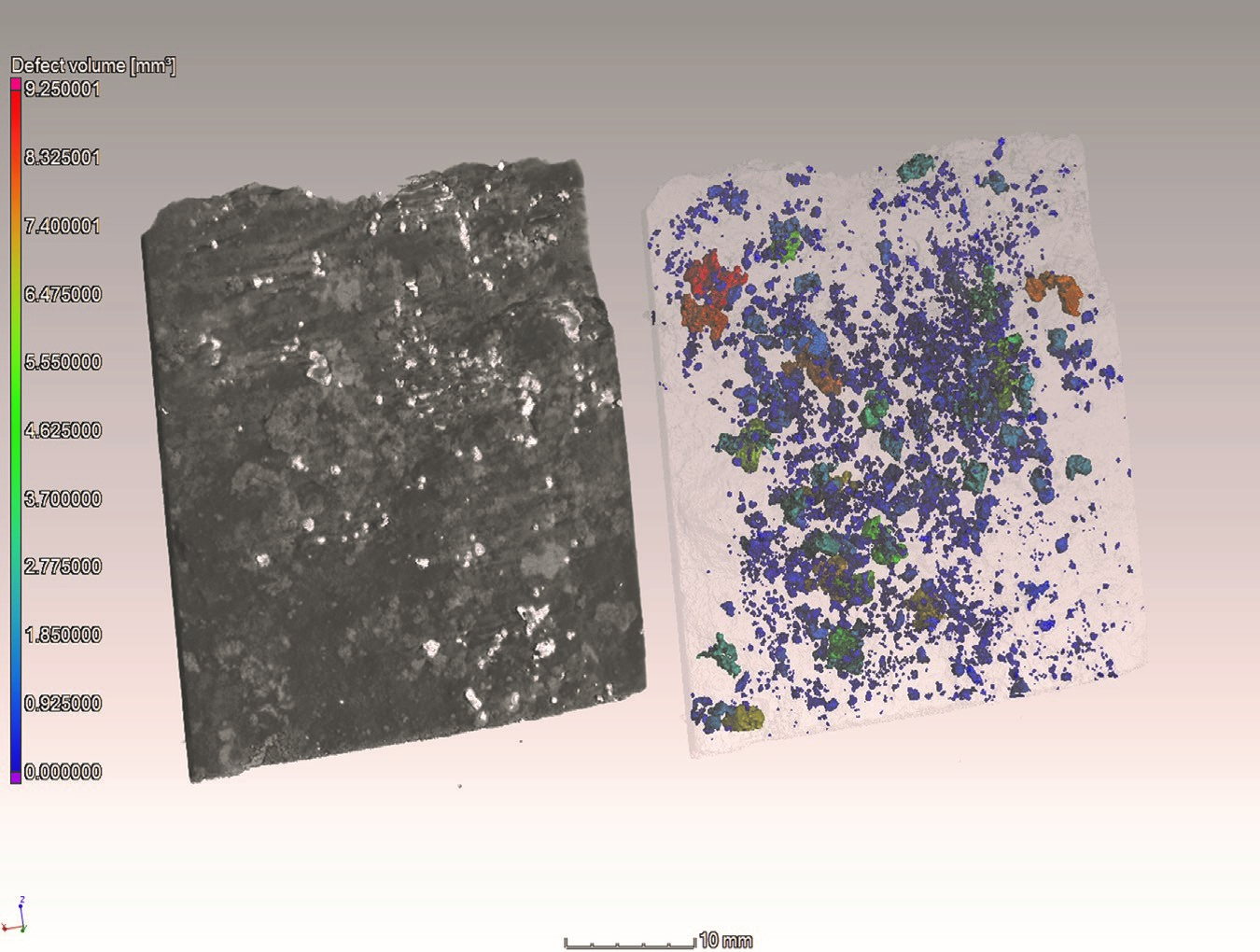

CT scan image of drill core W03, showing a color coded scheelite mineral grain analysis, with largest volume grains in red and smallest in blue (scan at 50 mm voxel resolution). (For interpretation of the references to color in this figure legend, the reader is referred to the web version of this article.)